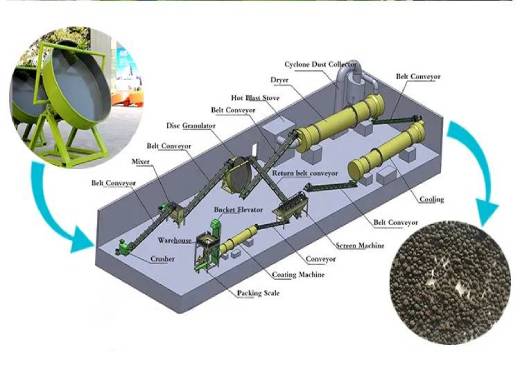

Zeolite Disc Pelletizer Production Line

What Granulation Method is Used in the Zeolite Pan Granulation Plant?

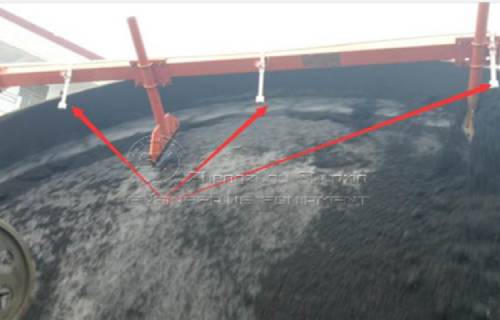

The zeolite pan granulation line mainly adopts wet granulation method. It usually uses liquid as binder to increase the adhesive force between fertilizer powdery. So the final zeolite pellets have a higher density and are not easy to pulverize. This kind of zeolite granules is easier to transport and store. Then how to add liquid in the process of disc granulation line operation? We especially design a spraying device above the pan pelleting machine. After the powdery material is transported in the disc pelletizer and the disc starts rotating. You can control the amount of liquid added by the spraying device. It can greatly contribute to improving the quality of your zeolite particles.

How to Design Pan Granulation Line for your Zeolite Pellets Production?

If you want to make high quality zeolite granules efficiently, besides suitable granulation manufacturing line, reasonable project design is also an aspect you need to pay attention to. SX can provide you with optimum granulation plant layout design out of charge. We will design it according to your actual conditions. It usually contains workshop area, budget, capacity, material, etc.

For example, if you plan to start a small scale zeolite granulation plant, we recommend you choose disc pelleting machine SXYZ-1800, SXYZ-2000 and SXYZ-2500. If you want to enlarge your zeolite pelleting production scale, it is advisable to use pan granulator SXYZ-2800, SXYZ-3000 and SXYZ-3600. And if your workshop area is not enough, it is an ideal choice to change belt conveyor to bucket elevator. If you also have any special requirements for pan granulation production line, you can contact us for customization.

What is the Process after Zeolite Pellets Granulation?

If you use disc granulator to make zeolite pellets, granules will have more moisture. Because this machine adopts wet granulation process, you cannot package after granulation. Hence, these processes can upgrade your pellets’ quality after pelleting.

Zeolite Pellets Production Line Reasonable Price for your Option

Why Use Disc Pelletizer in Zeolite Granules Making System?

From past data, we found that many ore pellets suppliers buy disc granulator for their ore pellets production plants. Why? From the feedback of our customers, we summarized two reasons as follows:

High Granulating Rate

Our disc granulation plant has a high granulating rate of over 93%. This means this production line can produce more required pellets with the same amounts of raw materials. So you can complete process powder into granules quickly and reduce the material waste.

Automatic System

Automatic material clearing plate above the sticking materials, improving service life of equipment and saving labor. It only needs a control panel box for granulation machine to work. Therefore, it can save more labors for some small scale disc pelletizer ore pellet plant.