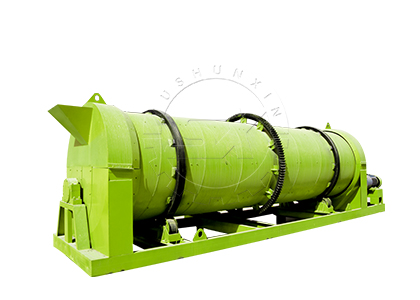

Rotary Drum Churning Pelletizer Plant

Rotary drum churning pelletizer plant for making fertilizer pellets takes the rotary drum churning pelletizer machine as the core. By setting up a drum churning granulation plant for making fertilizer pellets, you can expand the economic value of the rotary drum churning pelletizer to the most subsequently. This two in one granulating machine has been hot sale product in the fertilizer market. More and more people choose it as the tool to produce fertilizer initially. And how to have a rotary drum churning pelletizer production plant?

Here we are going to talk about it from the reasons that make you choose a complete rotary drum churning granulation plant, preparations, functions, cases and benefits of it, which will help you to choose a fertilizer production line that can satisfy your needs.

Setting Up A Rotating Churning Granulation Plant, Choose Us!

Many of our customers have evaluated that a new fertilizer production plant will ensure their granulation machines have a better performance and gain more benefits in a long time. As we customize the production line according to the granulation machines’ working principle.

For example, the rotary drum churning granulator’s main working method is agglomerate wet granulation. Through a certain amount of water or steam, the basic fertilizer reacts chemically fully after adding the humidity into the cylinder. Under certain liquid phase conditions, the rotation of the cylinder is used to make the material particles generate extrusion force to agglomerate into balls. The wet stirring tooth granulator uses the mechanical stirring force of high-speed rotation and aerodynamic force to granulation continuously. In this way, the pellets moisture are too high to package. You must need to equip a dryer and cooler to control the moisture efficiently.

Therefore, we can make your rotary drum churning granulation plant has a stable and continual production, which can cut a lot of time and money consuming.

Breakthrough: Drum Churning Pelletizer Plant Has Higher Productivity in the Plant

The reason that you choose rotary drum churning pellerizer in your production line is because it has great advantages than other granulating machines that attract you. Below you can feel that how the design and granulation ability of the drum churning granulator makes the production line has stronger production ability and perfect performance.

Actually, this two in one organic fertilizer granulator is developed based on the rotary drum granulator. The feed inlet and the fertilizer outlet are all closed. There are rings inside to increase resistance and prolong the raw materials staying time. The rotary drum churning pellet equipment’s main axle is not in the center of the tube. The axle turns to the right and the tube turns to the left. These are unique points different from other granulators. And their designs make the production line can can make high hardness fertilizer pellets, which are not easy broken during the convey and transportation.

Rotary drum churning pelletizer machine for making fertilizer pellets use high-speed rotation, mechanical stirring and the resulted air power to mix, granulate, spheroidize the fine powder materials continuously, so as to achieve the purpose of granulation. The particle shape is spherical, the sphericity is ≥0.7, the particle size is generally between 0.3-3 mm, and the granulation rate is ≥90%. Under the function of mixing and crushing machines in the fertilizer drum churning granulating machine, the waste and unqualified pellets can be collected and recycled to granulate fertilizer. In this way, there is no wonder that our plant have high granulation rate.

In the organic fertilizer drum churning granulation line, there are usually seven steps.

What Advantages Your Fertilizer Pellets Have Which Made by This Granulation Production Line?

As we mentioned above, our fertilizer granulation line by rotary drum churning granulating machine has excellent performance. And the final products-pellets’ quality is the most important in the whole production line. Therefore, what high quality fertilizer pellets can you get by the drum churning granulating production line?

High organic matter.

The particles produced are spherical. The organic content can be as high as 100%, which realizes pure organic granulation.

High hardness pellets.

The granulation has no edges and corners, and the powder rate is extremely low. Spherical particles have no sharp angles after granulation, so the pulverization rate is extremely low.

High production efficient.

As the machine’s granulation rate is more than 90%, people can make full use of powder granules. It can make fertilizer pellets 5-8 tons per hour. It is easier to meet the requirements of mass production.

What Need You To Prepare for Setting Up A Two In One Granulation Machine’s Production Line?

Design for your factory.

Before the delivery of new type two in one granulation line arrives at your factory, you need to set up the factory already according to the factory layout and diagram. Thus, you can place each part of the line quickly, then you can test and operate the production line into use at the fastest speed.

Elements for fertilizer production.

Besides a preparation for factory, the elements needed in production are also needed to prepare in advance. For example, you need to get ready for tons of raw materials and other addictive. The energy which you are going to use to provide power for the machine’s running. Besides, you also need to place the labor in the right place to ensure there is no malfunction.

Manual for installation & maintenance.

Our factory will send professional engineers and workers to help you install the whole rotary drum churning fertilizer granulating plant. And we also send using manual and guidance about installation, maintenance and repair methods. But it would be better if you have read them before. In this way, you can get much more familiar with your production line. And we can also solve your questions and problems efficiently.