Organic Fertilizer Granulator Machine

Organic fertilizer granulator machine makes high quality fertilizer for use. To produce higher quality organic fertilizer, it’s necessary for you to choose a reliable granulation machines’ manufacturer. Our factory has a complete granulation machines’ production line. It works normally every day. We also have patent certificates like CQC, CCT, SON etc. to prove our granulating machines’ quality. What’s more, we can custom your ideal organic fertilizer pellet making machine and its production line according to your needs and preferences. It’s not difficult for our professional working teams. You can custom your organic fertilizer granulation machine’s scale, granulation method, organic fertilizer’s features and raw materials. We are going to talk about these topics in the passage. There is also one real case from our customers for your reference.

We Have Different Scales of Organic Fertilizer Granulating Machines in Our Factory

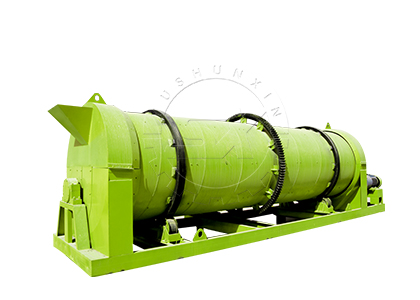

Generally, there are five types of granulating machine for making organic fertilizer: new type organic fertilizer granulator, rotary drum churning pelletizer, rotary drum granulator, disc granulator making machine and flat die pellet making machine. Besides, the three machines later among them can also make compound fertilizer pellets. Different machines have different structural designs and production capacities. And you can custom your organic fertilizer production scale by choosing the right granulation type.

In general, we have three production scales of our organic fertilizer granulation machines.

Organic fertilizer flat die pellet making machine is suitable for a small scale organic fertilizer production. It can produce pellets 0.08-2.5 tons per hour

New type organic fertilizer granulator, rotary drum churning pelletizer, and disc granulator making machine. The first one granulation machine can make organic fertilizer pellets 1-8 tons per hour, and the second one can make pellets 5-8 tons per hour, while the last one can make fertilizer pellets 0.02-6 tons per hour. Their production capacity is not too low, or not too high. You can choose them for your medium organic fertilizer pellets mill, which can adjust to the market needs flexibly.

Next, the rotary drum granulation equipment can produce organic fertilizer 1-30 tons per hour. It’s the granulation machine which has the biggest production capacity in our factory. You can have more than fifty thousand tons of production capacity easily in one year.

Tempus eget urna id, maximus commodo odio. Lorem ipsum dolor sit amet, consectetur elits sadips. Praesent alis lacus. Nunc at vulputate justo.

Wet Granulation Technology of Hot Sale Organic Fertilizer Granulation Equipment

Rotary drum granulator and disc granulation machine are two hot sale organic fertilizer making machines. And they both adopt the wet granulation method. Take the example of rotary drum’s wet granulation process. Besides the two hot sale organic fertilizer granulation machine, new type organic fertilizer granulator and rotary drum churning pelletizer also adopt the wet granulation. They both have requirements for higher moisture.

However, the flat die granulator uses dry granulation. The moisture doesn’t need to be too high, which is usually under 10%.

It’s your freedom to custom your organic fertilizer granulation machine by the granulation method. Wet granulation and dry granulation both have their advantages. Besides the granulation machines’ capacity and granulation method, there are also other aspects that need you to consider. You can have a view about them subsequently.

Our Granulator Machines Make Beautiful Shape, High Granulation Rate and Hardness Organic Fertilizer

Apart from the features of granulation machines for organic fertilizer, the organic fertilizer pellets’ quality made by our machine is also very important. We can compare the pellets’ shape, granulation rate and hardness later.

How To Granulate Different Kinds of Organic Fertilizer with Our Machine?

Organic fertilizer is made by fermentation of poultry and livestock manure. The organic fertilizer can be used directly or sold in bags after being granulated by a granulator. There are many raw materials are suitable for granulating machines making organic fertilizer, such as, poultry manure, straw, soybeans etc. Here we can understand how to pellet different kinds of organic fertilizer with our machines by some examples.

According to the information above, you must have a basic plan to custom your organic fertilizer granulation production initially. But you may still have questions. We sold our organic fertilizer granulating machines and their product lines to customers overseas for many years, which give us many valuable experiences so that release your worries. Here we can give you some ways to solve them. You can also contact our customer service directly.

Q:The quality of the iron and the thickness of the iron we used in our granulating machine.

A:The main material for our equipment is boiler steel(Q235B),and some parts are normal carbon steel. And for packing machine, the inner material is stainless steel. Different machines and different models have different thickness, but all of these thickness are national standard.

Q:The life expectancy of organic fertilizer granulating equipment.

A:The life expectancy of organic fertilizer granulating equipment is usually 8-10 years. We will also have a one year warranty. If there are some problems with granulating machine, we will repair and even change it for you. But it can run normally for a long time as long as you operate it right and maintain it timely.