Feed Pellet Production Line

It is a wise choice for you to build a full feed granules granulation production line. Hence, if you are a new manufacturer for producing and selling feed pellets, you should set up a complete feed pellets making line to help you start scaled and automatic production. Instead, if you already have a full set of pellets granulation lines, it is also necessary to know more about how the feed pellet production line works. Because you can’t make sure whether the single feed pellet granulation machine can adjust to your old granulation line perfectly. Is the production line design reasonable for feed pellet granulation machines? Is it easy and worthy for you to adjust the factory layout for feed pellet granulator? If you are one of them, this passage will be very fitting for you.

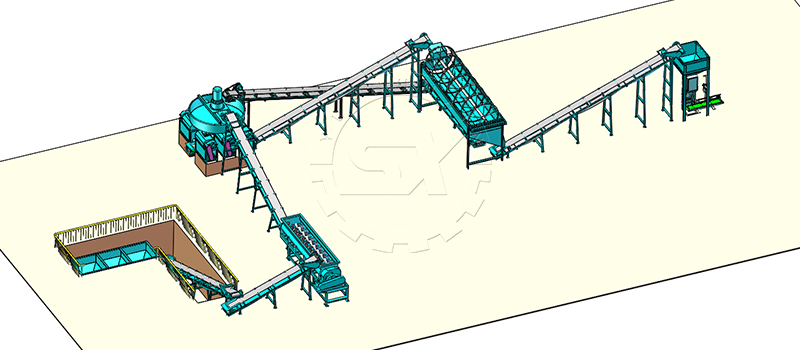

Here we are going to talk about our feed pellet production line subsequently. The topics are about the feed granulating machines used in the plant, working principle of the production line, the other important machines you need, raw materials’ choosing and processing, and our service’s brief introduction. Therefore, you will choose a much satisfying feed pellet production line for yourself.

What Benefits Can You Get by Setting Up A Feed Pellet Granulation Production Plant?

In our factory, flat die granulator is the main machine type for making feed pellets. Thus, flat die granulating equipment is the core of your whole feed pellets granulator production line. After you know the reasons for having a customized feed pellet mill plant, how about the benefits? What can you get by setting up a feed pellet granulation production plant? There are mainly two advantages for your reference.

Our feed flat die granulating machine can satisfy your requirements for the fertilizer pellets significantly. Under the whole granulation line’s function, you can get much better pellets than the single flat die granulation makes.

For example, if you have put a polishing machine into the feed pellets granulation plant, you can turn the columnar particles pressed by rollers into balls. The shaping procedure only needs to operate one time and there is no return materials produced. Then you can win many other feed pellet manufacturers on the pellets’ beautiful shape.

Wherever there is a precaution, there is no danger. With a complete feed pellet granulation line, you will enjoy a longer service life provided by granulating line. As each part of the production line are closely related with each other, which have down the materials’ damages to the operating machine greatly. It’s period of use is up to 7-8 years.

In this way, you can also cut extra money and time cost by introducing feed pellets granulation line for one time.

Raw Materials that You Can Add Into the Feed Pellet Production Line

Before you operate the feed pellets pelletizer production line, it would be better that you have prepared the raw materials before.

Like corn, soybean meal, rice husk, grass, straw, etc. are the most suitable raw materials for feed pellets granulation. You can have much more smooth and beautiful pellets because they are much easier to crush into powdery and mix with other materials. As a result, there will not be too large blocks and impurities to handle with. Besides, if you want to make pellets much more beautiful, as we mentioned above, a polishing machine will play an important role.

And how do we turn these materials into feed pellets? Below is a comprehensive and detailed description of it.