Compound Fertilizer Granulator Equipment

Compound fertilizer granulator equipment is one important type of granulation machines in the fertilizer business. Therefore, our factory, as a leading fertilizer production manufacturer, has developed three kinds of highly efficient granulation machine to produce compound fertilizer: rotary drum granulation machine, disk granulation machine and double roller granulating machine. They have different advantages in the process of making compound pellets. Below we are going to introduce the compound fertilizer granulator making machines from their models, working principles and advantages and cost to guide you choose an appropriate granulating machines for making compound fertilizer subsequently.

What is a compound fertilizer granulating machine?

Compound fertilizer granulator is widely used in making powder compound fertilizer into granules. Because the granular compound fertilizer is not easy to agglomerate and convenient to transport and store. Therefore, more and more fertilizer manufacturers use granulating machine in their complex fertilizer production lines. As a professional fertilizer equipment manufacturer, YUSHUNXIN designs three types of pellet making machine for your choice. They are disc granulator, rotary drum granulating machine and double roller extrusion pelletizer. They employ different granulation methods to granulate compound fertilizer. If you are interested in them or want to know more, please contact us immediately.

3 Highly efficient compound fertilizer granulator for sale

As mentioned above, there are three types of granulating equipment suitable for compound fertilizer making. Disc granulating machine, rotary drum granulator and double roller extrusion pelletizer. They can help you turn powdery complex fertilizer into particles easily. Following is some information about them:

Disc pelletizer

If you want to buy a economical granulator for your compound fertilizer making, disc granulator is an excellent choice for you. On the one hand, it has three discharge ports, which are convenient for intermittent compound fertilizer production operations. So it can greatly reduce labor intensity and improve labor efficiency. And it is made of Q235B boiler steel, which is wear-resistant, anti- corrosion. So our pan granulating machine has long service life. On the other hand, its granulating rate can reach more than 93%, which can reduce waste of chemical materials. And compared with other compound fertilizer granulators, it has a favourable price. So it is suitable for those who don’t have enough budget.

Rotary drum granulator

If you need a pellet making machine for large scale chemical fertilizer production. We recommend you to choose rotary drum granulator. Because it has higher capacity than other granulators and its largest capacity can reach 30 t/h. And whether you plan to manufacturing high, medium or low concentration complex fertilizer. Whether you want to prepare compound fertilizer by hot or cold granulation. Our rotary drum granulating machine can fully meet your needs. Therefore it will be a good partner with your compound fertilizer production.

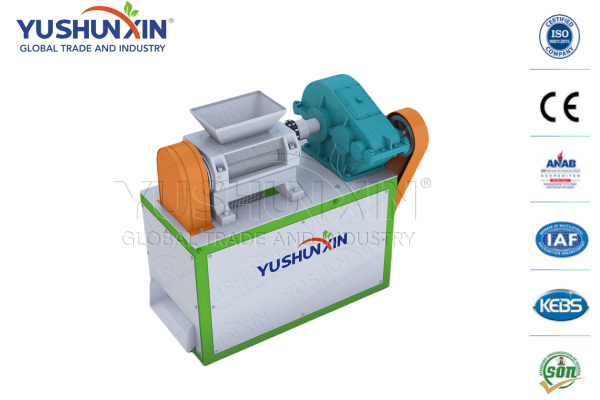

Double roller extrusion pelletizer

If your chemical material has a low moisture if below 10%, double roller extrusion pelletizer is your best option. Because it makes compound fertilizer into pellets mainly by pressing force. It nearly doesn’t require water. So you don’t need to spend money on subsequent drying and cooling. Therefore, if you want to produce compound fertilizer at a low cost, double roller granulator can also help you a lot

What granulation method you can use to make compound fertilizer pellets?

Do you know what granulation method you can use in granular complex fertilizer making? In general, there are two granulation methods for your choice: wet granulation method and dry granulation method.

How to choose a trustworthy compound fertilizer granulator manufacturer?

How can you find a trustworthy granular compound fertilizer machinery manufacturer? Here are the things that you need to know.

The compound fertilizer granulator equipment is easy to operate. Simple granulation machine structure makes the operation and maintenance easy for you. You turn on the button, and then watch the raw materials’ adding and machine’s normal running is well. Our most compound fertilizer granulators’ production has achieved automatic or semi-automatic.

It makes compound fertilizer pellets keep nutrition. Because the powder compound fertilizer releases nutrients quickly by wind or water. As a result, you may use a large quantity of no effect compound fertilizer. After granulation, the area between the granular compound fertilizer and the air is much smaller. The pellet’s structure is much closer, which is not easy to lose nutrients quickly.

Thus, it makes compound fertilizer convenient to store and transport. Besides, powdery compound fertilizer is easy to lose under forces outside. After granulation, the pellet’s structure is much closer. It helps prevent the pellets’ layering and sticking, which makes mechanized fertilization much more convenient.

How To Cut the Costs of Buying Our Complex Fertilizer Granulation Machine?

Cut the cost of buying a complex fertilizer pellet machine, which will lower your burdens of budget. Choosing the cheapest one among all kinds of factories, or bargaining with the manufacturers will be easier for you. What’s more, you need to find the core in the compound fertilizer granulator’s trade. The key point is whether our compound fertilizer pellet machinery deserves your trust. If it deserves, then you can cut the cost of time, money and wasted effort.

Here are three tips for you to cut the cost of buying a compound fertilizer granulation machine.