Cat Litter Fertilizer Granulation Plant

Now more and more people keep cats, so the demand for cat litter is also increasing. This has attracted many manufacturers to invest in this project. But how to produce cat litter pellets? In fact, its production process is very similar to that of compound fertilizer. Because most of the raw materials for cat litter granulation are bentonite, the process is basically the same as the production of compound fertilizer. For this, the cat litter fertilizer granulation plant you deserve. No matter what equipment you need, SX can fully meet your needs.

Breaking News

In order to thank our customers for choosing SX cat litter equipment, we have launched a major event. As long as you purchase an SX disc granulator, we will give away a cat litter formula worth a thousand dollars. There are five types of cat litter formula for your choice. If you are interested in this event, please contact us.

How to Choose Materials for your Cat Litter Fertilizer Manufacturing?

For cat litter preparation, the first step is material selection. For this, there are two items you need to focus on when choosing the materials for cat litter fertilizer production.

Cat Litter Fertilizer Making Materials Types

Cat litter making, is prepare fertilizer which contains two types of materials-organic and inorganic material.

Organic Material

If you want to make cat litter pellets with rich organic matter. You can use sawdust, confetti, grain, bean curd, cornmeal and pine wood, etc as material.

Inorganic Material

When you want to increase the inorganic content of your cat litter fertilizer. Bentonite, zeolite and silica gel are excellent options for you.

Cat Litter Preparation Materials Shape

Provide you plan to produce cat litter fertilizer with fertilizer granulation plant, we recommend you choose powder chemical materials.

What Can you Do to Upgrade your Cat Litter Fertilizer Making Line?

If you want to make cat litter fertilizer in a simple manner, you only need to buy batching machine and granulation equipment. However, provided you plan to upgrade this cat litter pellets manufacturing system, you also need to purchase machines as follows:

Coating Equipment and Cooler

Coating machine can add white gypsum powder to your cat litter pellets. Which have strong water absorption and can prevent sticking and nutrient loss. Then you can cool the finished fertilizer.

Packaging Machine

This is the final step of cat litter fertilizer making. After processing with our automatic bagging machine, you can transport, store and sell your cat litter pellets in an easily way.

How many types of granulators are suitable for making cat litter fertilizer?

In order to make cat litter fertilizer easier to transport, store and sell, most cat litter plants prefer to process cat litter fertilizer into pellets. For this, it is essential to buy suitable granulation equipment. Here, we recommend you choose the following three compound fertilizer granulation machines. Pan granulation, rotary drum pelletizer, double roller granulator and flat die granulator.

Disc Granulator for Small Scale Cat Litter Fertilizer Granulation

Provided you need a small scale granulation machine for cat litter fertilizer processing, disc pelletizer is an excellent choice for you. It has a capacity of 1-6t/h, which can fully meet your requirements of small scale capacity. In addition, because it relies on inclination angle of disc and spraying device to granulate cat litter pellets. The final cat litter pellets have a higher hardness, which makes it more convenient for use.

Rotary Drum Pelletizer for Large Scale Cat Litter Fertilizer Particles Manufacturing

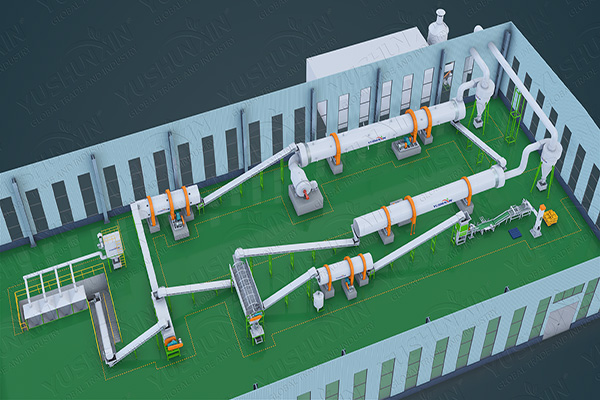

When it comes to large scale cat litter fertilizer granulation, we recommend you choose rotary drum granulator. Using it, you can even prepare 30 tons of cat litter fertilizer granules an hour. Moreover, with designs of rubber lining, clean holes and lift plates, it can produce cat litter fertilizer with less sticking. That is , long service, less material waste and higher granule making efficiency.

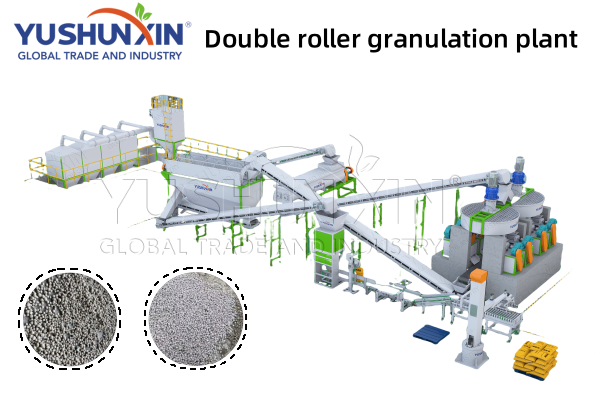

Double roller granulator for low content moisture material pelleting

The above two granulators both adopt wet granulation method, which uses liquid as binder to enhance the cohesive force between materials. But is there a pelletizer of dry fertilizer granulation? For this, SX can offer you double roller granulation equipment. It mainly relies on the extrusion force of two rollers to make materials into cat litter fertilizer particles. It is nearly no water involved. So you don’t need to buy dryer and cooler for double roller fertilizer granulation line. Then this machine also can greatly reduce your budget for granular cat litter fertilizer manufacturing.

Flat Die Granulator for Tofu Cat Litter Pellets Production

When you want to buy equipment for producing tofu cat litter pellets as tofu or cornmeal as raw material, we recommend you choose our flat die granulator. Because this machine is also called feed pellet machine. It can produce granules that other granulators cannot. In addition, if you use this equipment to produce tofu cat litter fertilizer, you don’t need to dry and cool after granulation. Because it belongs to dry granulation, this process can not only save costs, but also have high efficiency in producing granules. What’s more, it produces the tofu cat litter pellets that is environmentally friendly and can be condensed for easy cleaning. And no dust, non-toxic, harmless to cats and people.

How to produce cat litter granules with the required size?

Then for particle size, if you want to make cat litter granules with a diameter of 1 to 2 mm. For this, we recommend you choose disc granulation machine, it can meet your requirements of preparing 1-8 mm cat litter fertilizer pellets. But how to adjust the size of final cat litter granules you produce? For pan granulation, there are two methods:

How to Make Unfinished Cat Litter Pellets in Fertilizer Granulation Plant?

Unfinished cat litter is bentonite small fragments pellets, you can buy the finished product directly. However, the finished product has different particle sizes, and the quality has not been screened. If it is sold directly, the effect will not be good. So we recommend that you can first transport the material to the screening machine through the feeder and belt conveyor for sieving. You can sieve out bad quality and variable size particles. The last remaining good pellets you can pack directly. In addition, the production process of this kind of cat litter is very simple, but the dust is relatively large. We can also solve this problem. You can add a dust cover as mentioned above.

What do you need to tell us if you want to buy a cat litter fertilizer granulation plant?

If you are interested in cat litter fertilizer production line or cat litter fertilizer machine or you want to buy other fertilizer equipment. You can contact us to tell us some information about you or your company. The more information we know, the better design project we can provide you. It includes your country, materials, capacity, factory space, which fertilizer production line or equipment you need, etc. In addition, you need to tell us your name, telephone number and email. So we can contact you for further discussion. We will design an ideal layout according to your requirements.