Bulk Blending Fertilizer Production Line

Bulk blending fertilizer production line, or, BB fertilizer production line, which produces compound fertilizer of different proportion of nitrogen, potassium and phosphorus. In general, the whole production line includes batching, mixing, packing process:

Here we are going to introduce more about our bulking blending fertilizer production line, and you can take it for your reference before buying.

Reality Necessity for Setting Up A BB Fertilizer Plant

1.Fertilizer market’s urgent needs for BB fertilizer plant.

BB fertilizer can provide multi-elements for plants’ growth. Besides, the cost and procedure are also much easier than other compound fertilizer. It is popular in agriculture nowadays. But, in abroad, most BB fertilizer are mixed before using and transported for a short journey. Thus, it is difficult to go on production at a large scale. Fertilizer market has a larger demand for BB fertilizer plant’s production.

However, our BB fertilizer plant can achieve large scale, stable and continuous production automatically through its working method. It will make you gain advantages in making BB fertilizer.

2.Economic benefits by having a BB fertilizer making factory.

As we mentioned above, bulk blending fertilizer is made of nitrogen, potassium and phosphorus by simple mechanical mixing.There is no significant chemical reaction happens in the production. Many unprofessional BB fertilizer making plant have been attracted by the potential economic benefits. But most of them don’t have advanced technology, or smart machines to support them to produce high quality BB fertilizer pellets.

Instead, our factory can batch the different proportion of N, P, K exactly. The batching precise can up to ±0.2% degree. Our BB fertilizer pellets usually have the advantage of uniformity, dry, and moderate intensity for commercial use.

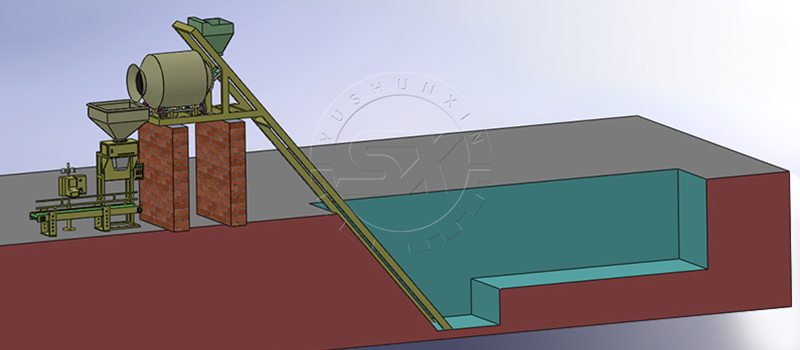

Underground Layout Characteristics of BB Fertilizer Granulation Line

How do we design the BB fertilizer production line? Different with other compound fertilizer production line, it’s layout is underground. In details, the batching part will go on production underground. Why do we design it’s layout like this? There are two obvious advantages:

What’s more, you can also put the whole BB fertilizer production line on the ground. Bucket elevator and other lifting equipment to lift raw material into mixer.

Bulk blending fertilizer is one type of compound fertilizer, it’s production line also has similar points like the compound fertilizer granulation line:

However, there are also some differences between bulk blending fertilizer production line with other compound fertilizer plant. Production time difference is one important point. In most cases, bulk blending fertilizer’s making and adopting in one day. It doesn’t take the storage into consideration. In this way, people have strict standard to BB fertilizer’s production than compound fertilizer. Because later production go through chemical reaction and other mechanical forces to granulate, which will remain state more easily.

Nowadays, more and more agriculture needs long time storage BB fertilizers’ production. Thus, it will have higher production standards to BB fertilizer pellets’ uniform and dry surface, and moderate hardness. And our production line for making bulk blending fertilizer can satisfy this standard easily with the support of advanced technology. You can read it in the next part.

Working Machines in Our Bulk Blending Fertilizer Production Factory

BB fertilizer batching part: Automatic batching machine.

The batching system is controlled by computer. According to the ratio of nitrogen, phosphorus, potassium and additives in a 50kg bag of BB fertilizer, each proportion is independently measured. The batching accuracy can reach ±0.2%. Besides, the dynamic automatic batching system is much suitable for batching continuously. Therefore, your BB fertilizer plant can produce high accuracy of bulk blending fertilizer continuously.

BB fertilizer mixing part: BB fertilizer mixer.

BB fertilizer mixer is the most ideal machine to make BB fertilizer pellets for manufacturers. It feeds materials from the lifting tank directly, and discharge them from the mixer. Thus, there is no blanking in the procedure. Besides, it mixes material evenly through the special inner screw mechanism and unique three-dimensional structure’s forward and reverse operation. Therefore, it overcomes the mixtures chromatography and distributaries phenomena, which will happen because of different proportion of raw materials and particle size.

BB fertilizer packaging part: Single(Double) bucket automatic packing scale

According to the set weight, the mixed fertilizer is filled into the packaging machine. You can adjust the packaging standards like weight, speed etc. in advance. Then, they will be sent to the sewing machine station by the conveyor. The packaging accuracy can reach two thousandths significantly. By such an accurate packaging machine, your BB fertilizer production line can make high quality BB fertilizer pellets for sale.

How Much Need You To Pay for Having A Production Line to Make BB Fertilizer?

In the market, one set of BB fertilizer production line is usually about 180 thousand dollars for sale.

Though the BB fertilizer production line has a simple production procedure, to ensure the production quality of BB fertilizer pellets, we need to equip the production line with sophisticated machines. Therefore, our machines for making BB fertilizer all have patents in technology. They are ideal machines for making BB fertilizer. You can choose our machines without worries.

Besides, our company will give you the most considerate whole-sale services: