Bentonite Granules Production Line

How to Choose Different Types of Bentonite for your Bentonite Granules Manufacturing?

For bentonite granules preparation, the first step is type of bentonite granules selection. For this, you need to focus on it when choosing the type for bentonite granules production.

Bentonite Granules Making Types

Bentonite granules making is prepare fertilizer which contains sodium bentonite, calcium bentonite and organic bentonite. Then what properties can these three bentonites provide in you fertilizer making process?

How to Make Powder Chemical Materials into Activated Acid Bentonite Pellets ?

If you plan to prepare activated acid bentonite granules, which can help you make more profits. Our activated acid bentonite granules manufacturing line is an ideal choice for you. Because it can help you make powder activated acid bentonite into granules quickly and easily. Then what is the design of activated acid bentonite pellets plant?

Chemical Material Crusher

The finer the chemical powder, the better the final activated acid bentonite pellets(moisture of 25%) quality. Therefore, a suitable crusher is necessary for your activated acid bentonite fertilizer making. Here, vertical type crusher is excellent choice for you.

Drying Powder Activated Acid Bentonite

Because the moisture content of activated acid bentonite is about 25%, but it is required that the moisture content should drop below 6% for subsequent production. So you can use a dryer to remove excessive moisture.

Raymond Mill System to Powder

The finer the powder, the better the granules produced. So you need to use the Raymond mill system to further grind the dried powder to 200 mesh.

Reactor to Mixing

Then you can put this ground powder into the reactor. Add water and acid, stir them well and heat to 90-100°C for reaction.

Solid Liquid Separator

After that you can put the reacted slurry in a dehydrator to separate the solid from the liquid. The remaining solid materials are used for subsequent granulation production.

How to make bentonite pellets with different granulation method?

We have three fertilizer granulators to make bentonite pellets, which employ wet and dry granulation method.

Disc pelletizer to make small scale bentonite granules

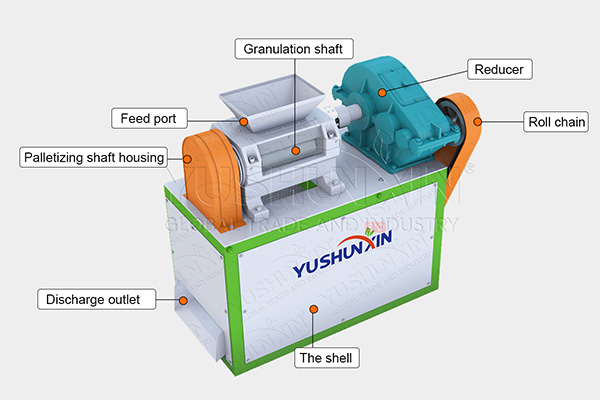

Double roller granulator at a low invest for bentonite pellets making

When you prepare to produce bentonite pellets at a low cost, we recommend you extrusion machine. Because it adopts dry granulation method, which reduce the cost of drying and cooling. And it needs the moisture of material about 5%. In addition, it can produce 1-2 t/h bentonite granules. So if you want to make small scale bentonite pellets, this machine is also suitable for you. Then the granules diameter is about 3-10 mm, you can adjust the size of roller skin to change the size of final product.

Rotary drum granulation machine for large scale bentonite granules production

How to make bentonite powder into pellet in a large scale? Using rotary drum granulation machine is an ideal choice. Besides models for small scale granulation, we also design various types of drum granulators for mass production of bentonite granules. For example, when you want to produce 8-15 tons of pellets per hour, we can provide you with SXZG-2080. Moreover, for larger scale fertilizer pellets manufacturing, you can choose SXZGZ-3210, which has capacity of 15-30 t/h. Usually, this pellet making machine can bentonite powder into granules within 3-6mm. Then how to regulate the size of granular bentonite during rotary granulation? Adjust moisture content or control the rotating speed of the drum. The higher the water content, the larger the size; the lower the water content, the smaller the size. The higher the rotating speed, the smaller the size, the lower the rotating speed, the larger the size.

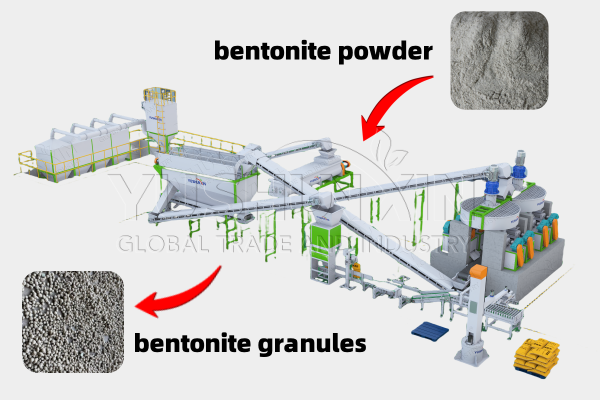

How to setup a bentonite granules production line?

If you want to setup a bentonite granulation plant, buying pellet making machine only is not enough, it is necessary to choose other bentonite processing machines to establish a professional bentonite granulation line. In this process, cost and factory area are two items you must pay attention to. So to establish a bentonite granulation factory, you need to do the following things.

What equipment is needed in a bentonite granulation line?

When you plan to create a bentonite granules production line, besides granulator, you also need to buy batching machine, crusher, mixer, screener, dryer, cooler, dust collector, dust fall room, coating equipment, bagging machine and belt conveyor. When it comes to bentonite granulation line with dry granulation, you may not need to purchase dryer and cooler.

How much does a bentonite granulation plant setup cost?

Cost also plays an important role in bentonite granules production line setup. It contains the costs of equipment, workshop building, energy consumption, worker employment, etc. Then because our bentonite granulation system has characteristics of low energy consumption and high automation. And as a source factory of fertilizer equipment, YUSHUNXIN can provide you with equipment at a favourable price. You can setup the bentonite granulation plant at a low cost.

What is the area occupation of a bentonite pellet making system?

The area occupation also will vary according to the capacity and configuration. Generally, a 5 t/h bentonite granulation line needs an area of 800-1,200㎡. And you need to prepare a 1,500-3,145 ㎡ site for a 20 t/h bentonite pellet making system installation.

How about the Final Bentonite Granules in SX’s Bentonite Pellets Production Line?

However, the final fertilizer granule is still the best way to test whether the bentonite granules production system is suitable for you or not. Hence, you can see some advantages about these bentonite granules.

Why should you Choose SX’s Granulate Dryer for Bentonite Granules Production?

The importance of the dryer can be seen from the above bentonite production process. So it is necessary to choose a good quality dryer. But why choose the granulate dryer from SX? Because SX specially designed a corresponding dryer according to the granulation characteristics of bentonite, which can help produce high-quality granular fertilizer.