Alfalfa Pellet Mill for Sale

Alfalfa pellet mill for sale is a granulating machine which use alfalfa as the main materials. Thus, you can turn alfalfa material into organic fertilizer for the growth of plants, and also can turn them into feed pellets for the cow feed, goat feed and so on. What’s more, you can not only recycle the high nutrient alfalfa, but also make profits from alfalfa. For this, alfalfa pellet mill is the best choice for you to dispose of alfalfa. And if you want to increase your capacity, SX can also design an alfalfa pellets plant for you according to your requirement.

In SX, we mainly recommend our alfalfa pellet mill for sale: flat die granulation machine. Below are the topics about it: the reason that you use alfalfa pelletizer, machine parameters and working principle, application places, and costs. It will be your freedom to read the part that you have interests.

How to Make High Quality Alfalfa Pellets?

When you want to make high quality alfalfa pellets, alfalfa pellets production line is necessary. Because it has a complete fertilizer machine, which can help you make high quality alfalfa pellets. So except alfalfa pellets mill, what machines can also help you produce alfalfa granules?

Alfalfa material drying machine

The alfalfa for making pellets should have the moisture content of about 10%. For production lower than 500 kg/h, natural drying by the sun is enough. But for large scale production, you can use a rotary dryer in the alfalfa pellet production line. Because the hot air in the dryer will contact the alfalfa materials. Then it will transfer heat to the material through heat conduction, convection, radiation, etc. Therefore, the temperature of the material will continue to rise and the moisture will continue to volatilize.

Grinder for powdery alfalfa

If you want to make high quality alfalfa pellets, grinding is necessary. Because the finer the powder, the higher the quality of the final particles produced. For this, there are three crushers for your choice. New type vertical crusher, straw crusher and hammer mill. You can use them to process alfalfa materials into small sizes, usually Φ3-5mm.

Alfalfa pellets Mill

As a processional fertilizer equipment manufacturer, we can provide you with a special alfalfa pellets mill for alfalfa pellets production. If you want to make alfalfa pellets less than 60 tons per day, we recommend you choose SXPM-400, which has a capacity of 1-1.5 t/h. Moreover, we can also provide you with SXPM-600, which can help you produce 2-2.5 tons of alfalfa granules. In addition, it can meet your requirements of making alfalfa pellets with different sizes. So we can offer you mold for 2-10 pellets making.

Cooler for final alfalfa pellets

When alfalfa pellets leave the pellet mill, their temperatures can be as high as 85℃ and moisture contents are high as 17-18%. For proper storage and handling of the pellets, their moisture content must be reduced to 10-12% and their temperature to about 3-5 ℃ above atmospheric temperature. So you can choose SX rotary cooling machine for pellet production.

Alfalfa granules packaging equipment

For easy storage, you can pack the pellets into bags. And the common weight of each bag of pellets is 15kg , 30kg, 50kg. Our automatic pellet packing machine has a wide range of 5-100kg/bag.

How to establish a alfalfa pellets production line?

It is mentioned above what equipment is used in the alfalfa pellets production line. So buying alfalfa pellets mill only is not enough. It is necessary to choose other fertilizer processing machines to establish a professional alfalfa granulation line. In this process, cost and factory area are two items you must pay attention to. For this, to establish a alfalfa granulation factory, you need to do the following things:

Why Do You Buy SX Alfalfa Pellet Mill to Make Feed Fertilizer at Low Cost?

If you want to make feed fertilizer at low cost, alfalfa pellets mill machine is the best choice for you. Why? There are five reasons for your reference:

| Model | Capacity(t/h) | Powder(kw) | Pellet Diameter(mm) |

|---|---|---|---|

| SXPM-400 | 1-1.5 | 30 | 2-10 |

| SXPM-500 | 1.5-2 | 37 | 2-10 |

| SXPM-600 | 2-2.5 | 45 | 2-10 |

How to Adjust the Size and Shape of Alfalfa Pellets?

If you want to know whether this granulator is suitable for your alfalfa pellets production, the spedification of granule is also an item you need tofocus on. Alfalfa pellets mill can help you produce cylindrical particles with a diameter of 2-8 mm. But different customers may have different requirements. How to adjust the sizeand shape to meet your requirements during flat die granulation?

If you make alfalfa pellets with flat die pelletizer, you can change fertilizer size by choosing different molds. As mentioned above, the alfalfa pellets mill machine produces granular fertilizer by pressing material into mold. In general, this size of produced fertilizer particle refers to the diameter of the cut surface of the hole in the mold. Here, SX can provide you with suitable mold for preparing fertilizer with any diameter within 2-8 mm.

The alfalfa particle manufactured by flat die granulator is cylindrical shape. But sometimes, you may want to convert them into round pellets. How to finish this task? Fertilizer polishing machine can help you a lot. This equipment is designed for reprocessing granular fertilizer particles with other shapes into spherical granules. And it also can help you improve the appearance of your fertilizer and make it more competitive. And in order to meet different needs of customers forcapacity, we especially design two- stage polishing machine for small scale fertilizer production and three-stage polishing equipment for large scale fertilizer manufacturing.

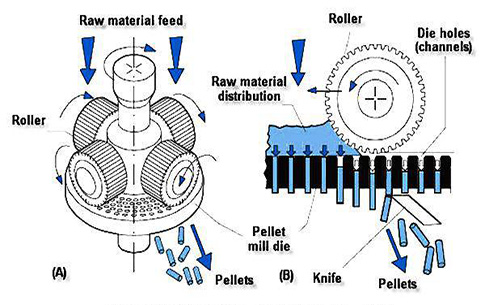

Significantly, in the process of alfalfa flat die pellet press machine, we can divide it into three parts mainly: break and separating part, transmission connection part and head working part.

(1)Break and separate part:

After you put into the alfalfa materials, they are pressed by the rollers. Then they’re going into the breaking device. You can separate the qualified pellets and the return material through this equipment.

(2)Transmission connection part:

hen the transmission connection parts are working, the electric motor will drive the pulley, V-belt, and reducer to rotate and granulate the fertilizer pellets. In addition, there is a transmission chain composed of sprocket and chain, which is the main motivation for driving the crushing and separate part. We also use the mutual work of the nylon pin coupling to drive the transmission reducer and the head working part.

(3)Head working part:

Then for the head working part, we use a pair of open wheels to ensure that the pair of rollers are synchronized. In addition, both sides of the active and passive shafts are composed of specific bearings and bearing frames, which installs on the frame.

If you have questions, it’s welcome you contact with our customer service. Especially, if it is convenient for you, you can visit our factory in Xingyang, Henan. We have already make preparations for your visit.

Wide Application of Our Alfalfa Pellets Granulating Equipment

It’s easy to find alfalfa as your raw materials for granulation.

Alfalfa pellets are a legume and a green manure. It has much kinds particularly, which you may haven’t noticed. You may find much more in the villages, mountains, furthermore, some farms have scaled alfalfa production. You can build your factory much closer to these places. After you buying our alfalfa pellets granulation equipment, it will cut extra transportation during granulation process.

The alfalfa pellets have a wide application range.

Alfalfa contains sufficient nitrogen, and phosphorus and potassium. The ratio of nitrogen, phosphorus and potassium is about 3:1:2, which is even higher than that of vermicompost. If there is not enough compost or vermicompost at home, this alfalfa pellet is a good supplement. Alfalfa pellets made by our granulating machine still have high nutrient ratio, and we can also add other adhesives to increase nutrient and keep fresh. They can promote all kinds of plants growth and provide feed for animals. It has applied widely in agriculture.

In this way, you can set our alfalfa pellets granulating machine much closer to the market. There will always have customers choose your cheap and wider scope of application alfalfa pellets.

Price Cost of Our Machine for Making Alfalfa Pellet Mills

Alfalfa pellet is valuable for money. A large bag of alfalfa pellets costs about $16, and you can use it for a whole year. In a daily fertilization, spread 1 cup of alfalfa fertilizer on 1 square meter is enough. Similarly, our flat die alfalfa pellets making machine is also valuable for money.

The price of one set flat die granultor in our factory is $2800-8100. In other factories, whose production capacity can reaches our level, but the price is much expensive, they sell at least $5000. 1-2 tons per hour of alfalfa pellets production capacity machine sells at least $3500 around. Some price does cheaper, 300-500 kg/h alfalfa flat die granulator sell $2900-7500. After this comparison, you can do believe that we are the most appropriate partner for you.

Price fluctuation is caused by the machine parts, policy and tax etc consequently. This will also not effect that our flat die alfalfa pellets making machine is deserve to buy. Our company has a professional team composed of experts, professors and senior engineers. And we have experienced employees who can provide the considerate whole-sale services for you accordingly. You will happy that buy our not others’ alfalfa pellets making machine indeed.