How to Start Large Scale Dolomite Pellets Making in Saudi Arabia?

This customer told us that for a project in Saudi Arabia, he needs a dolomite pellets production line and the expectant capacity is 15-20 t/h. Which pelletizer is suitable for this? Both rotary drum granulator and pan pelletizer are ideal choices for you.

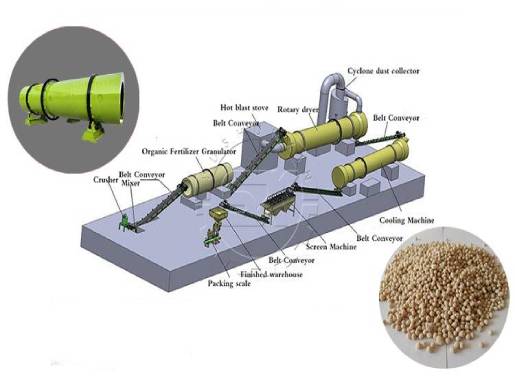

Rotary Drum Granulator for Easier Large Scale Dolomite Pellets Making

According to the requirements of this Saudi Arabian client for 15-20 t/h production of dolomite granules, we recommended him rotary drum pellet machine. Because Only need a drum pelletizer, you can finish this large scale dolomite granules manufacturing plan.You can buy SXZGZ-3210, which can produce 15-30 tons of dolomite granules per hour for you. In addition, whether you want to prepare high, medium or low concentration dolomite pellets, it can fully meet your needs. Because we equip it with an extra rubber lining, which has high performance in erosion resistance.

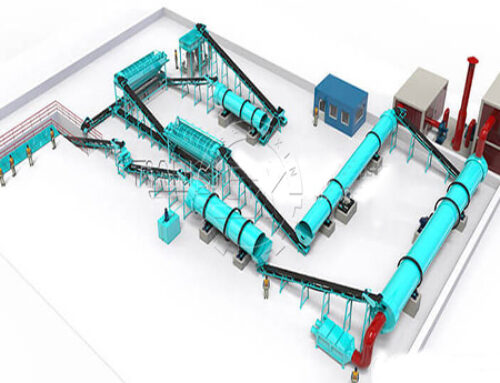

Pan Pelletizer for Processing Granular Dolomite Effectively

When we talked about the granulation rate of rotary drum granulation equipment is about 90%. This Saudi Arabian customer asked us that is there fertilizer equipment with a higher granulation rate? Of course. It is advisable to choose our pan pellet equipment, whose granulating rate can reach over 93%. That is, with the same amount of dolomite powder, the disc granulator can produce more granules. And there is less powder that needs to be returned to re-granulate. Then because the largest output of a disc pelletizer is 6 t/h. For 15-20 t/h dolomite granulation, you need to use 3-4 pan pelletizers.

How to Start Cow Dung Fertilizer Production in a Large Scale?

Then for particle size, the customer from Saudi Arabia wanted to make dolomite granules with a diameter of 2 to 3 mm. For this, we recommend you choose disc granulation machine, it can meet your requirements of preparing 1-8 mm fertilizer pellets. But how to adjust the size of final dolomite granules you produce? For pan granulation, there are two methods.

Adjust the Moisture Content

The higher moisture content, the larger size; the lower moisture content, the smaller size. Why? The high water content makes materials easier to stick to each other and combine with more materials. So it is easier to roll into larger fertilizer granules.

Change the Angle of Disc

The sharp slope, the smaller size; the slower slope, the large size. However, what you need to focus on is that it is advisable to keep the angle of disc between 35° and 55°.

Leave A Comment