Because of the rising demand for zeolite pellets and it has the ability to increase the ammonia retention capacity of the soil, more and more projects invest in making zeolite granules. For example, on 27th June 2023, a customer from the USA inquired about how to setup a 6t/h zeolite granules production line. This client told us “…complete line- from receiving raw materials zeolite rocks from the factory up to packing the powder fertilizer for zeolite rocks to produce zeolite pellets. With capacity 6 t/h … send me the layout , quotation…” The follow are the specific details of communication in this case.

What Equipment is Needed in a Complete Zeolite Granules Production Line?

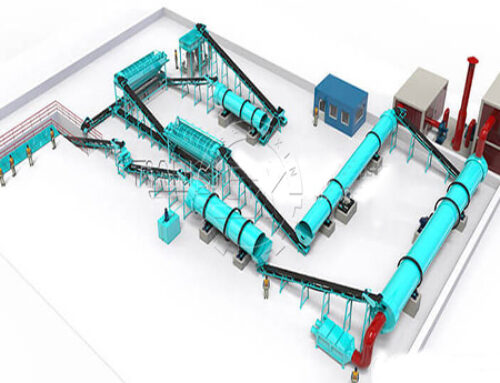

This American customer wanted to buy a complete zeolite pellets processing line- from zeolite rocks collection to granules packaging with capacity 6 tons per hour. Then during the subsequent communications, he asked us what equipment is needed in a complete zeolite granules production line in details? In general, it contains the following machines:

What is the Design of a 6T/H Zeolite Granules Production Line?

When you want to setup a zeolite pellets plant, factory area are also two aspects you must consider. Usually, the whole zeolite pellets manufacturing area is divided into three parts:

As the name suggests this is an area for zeolite rocks crushing. And in generally, it will vary with capacity. The larger the capacity, the larger the crushing area. For example, the customers from the USA wanted to use Ray mill system and crusher to prepare an area of 15*10m.

This area is designed for installation of equipment from granulation to packaging. For 6t/h zeolite granules manufacturing, it needs about 80*38m .

Besides the above two areas, you also need to prepare a place for finished zeolite pellets storage. However, this only needs a small area.

Leave A Comment